Case Studies

The Need: A high barrier, non-toxic, odorless, chemically stable, laminated material made with CPE (Cast Polyethylene) as a sealant layer PET 12µ / AL 6µ / ONY 15µ / CPE 90µ

The Challenge: Getting consistent and reliable film lamination with CPE

The Solution: The CPE layer is difficult to laminate – so you don’t see many companies capable of manufacturing film like this. This in-process pharmaceutical development project called for that CPE sealant layer, but were having trouble finding a steady quality supply. Our expertise in uncommon material lamination, combined with the aluminum and nylon layers, gives this material a superior barrier to moisture, a high tensile strength, and has allowed the customer to maintain absolute sterility for their product.

The Need: A laminated film using VMPET to increase barrier properties

The Challenge: Laminating VMPET to VMPET

The Solution: VMPET is extremely useful for it’s high barrier to low cost ratio. However, the metallization process makes it a difficult to laminate in certain circumstances – like when sealing to a similarly treated material While many manufacturers still run into issues when sealing multiple layers of VMPET together, our decades of experience make us proud to call that one of our areas of expertise

The Need: A Flexible Package for an Aggressive Gun Cleaning Solution (Wet Cloth)

The Challenge: Keeping the Towelette Wet, and Preventing Delamination / Separation

The Solution: A lamination of film foil and polypropylene specifically designed for packaging aggressive chemical contents which might cause layer separation or structure delaminating. The material combination for this film allowed the customer to safely package their product in a flexible package. Not only did the material withstand the harsh chemical contents, it also kept the cleaning towel wet because of its strong moisture barrier properties. Other products which benefit from such a structure are moist towelettes, oil, or alcohol impregnated media, essential oils, incense, and cosmetic products.

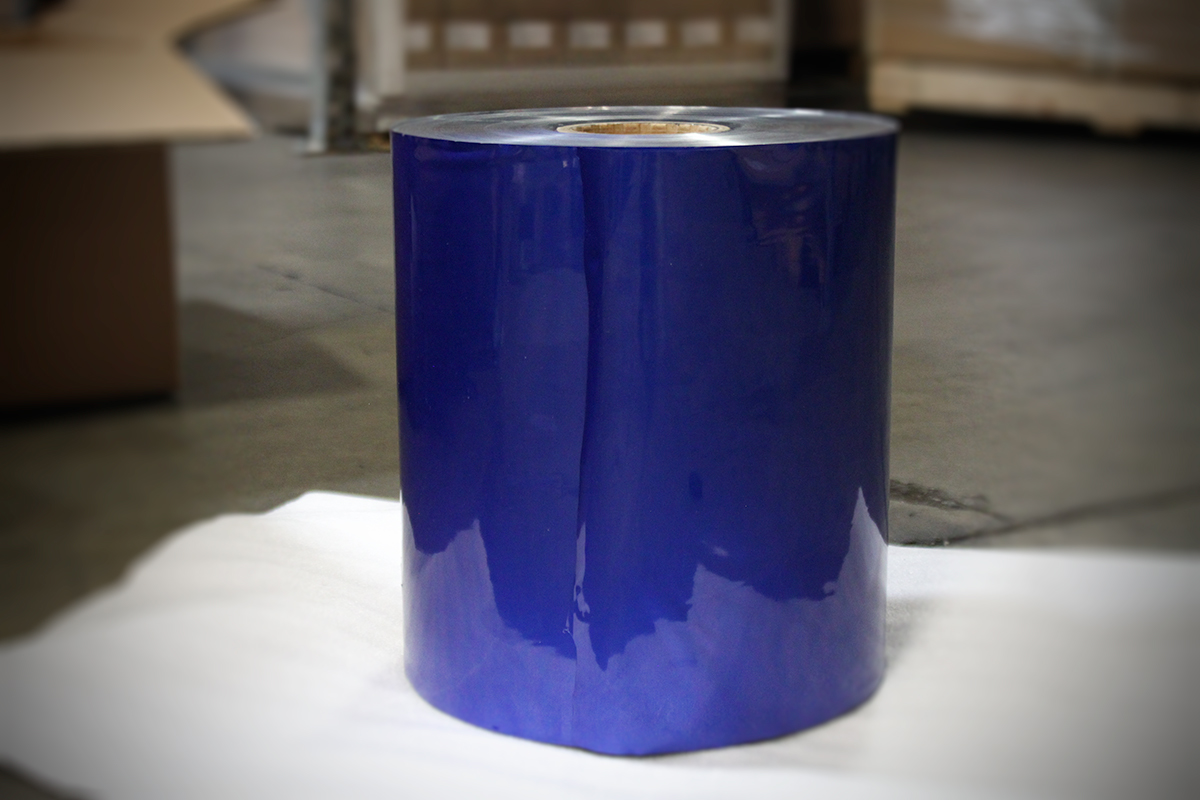

The Need: An Exact Pantone® Match on a Foil Film

The Challenge: Determining the Color Adjustment Required for a Foil Substrate

The Solution: After some educated guesswork, several possible blues were chosen and film samples were created to determine the closest match. The packaging technicians had to factor in how the silver under layer would affect the final color, and explain to the customer that running the exact Pantone® color they wanted would not result in a final film of that exact color. One of the finished film samples was a match and was then produced in mass.

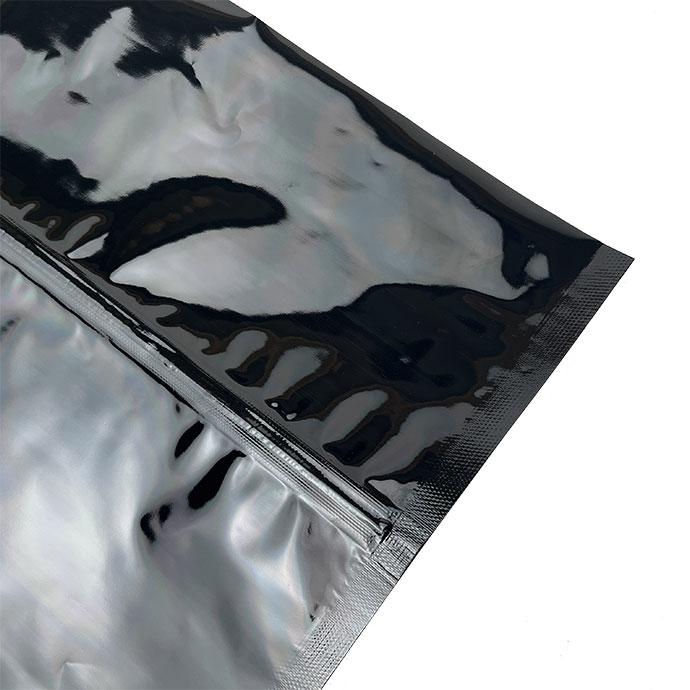

The Need: A Bag for Hops with High Seal Bond Strength and Excellent Barrier Properties

The Challenge: Creating a Solid Seal Through Oily / Powdery Products

The Solution: A film with a special sealant layer, plus extreme barrier protection against oxygen and moisture. The advanced inner sealant layer meant that debris along the seal line would not prevent a solid seal. This increased production speed and safeguarded product freshness.

Interested in Learning More?

Whether you need a small volume order that other suppliers will not handle, or a custom lamination that is outside a supplier’s wheelhouse, our team can connect you with an appropriate specialist to deliver the solution you need.