What Is Custom Film Lamination?

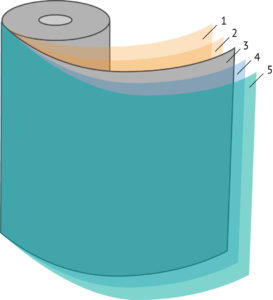

A custom film lamination is a layered film combination engineered to meet highly specific customer requirements and applications. Custom film laminations address packaging challenges as simple as achieving an exact Pantone® color, or as advanced as providing high temperature or aggressive chemical compatibility.

-

Sealant Layer

-

Tie Layer

-

Barrier Layer

-

Tie Layer

-

Exterior Layer

How Are Custom Film Laminations Used?

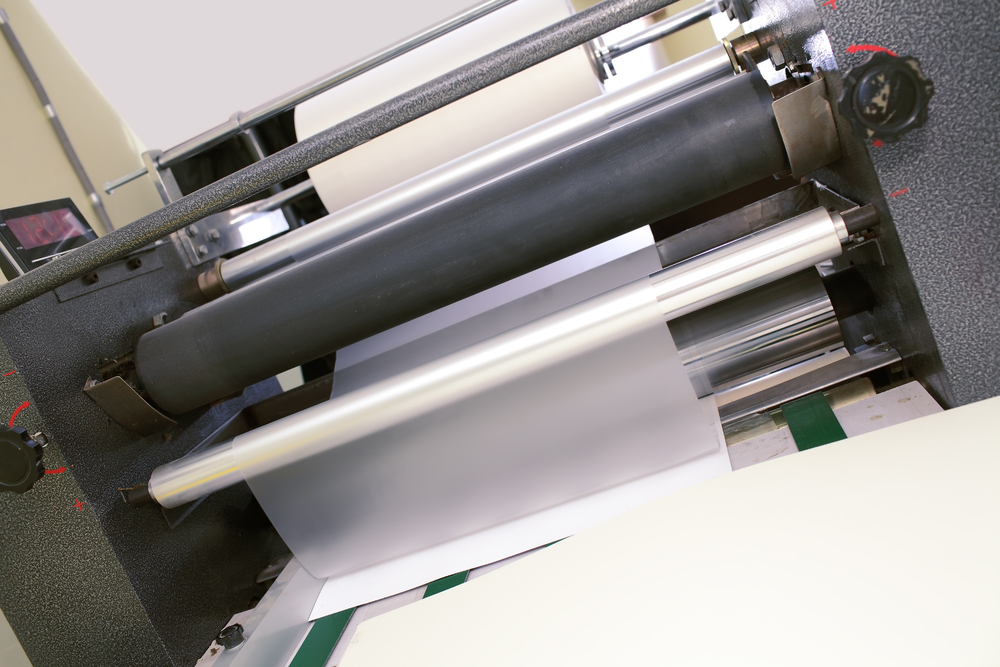

Flexible packaging is a growing market, and the demands for custom film laminations grows as companies transition from rigid containers to flexible packaging. The appeals of a flexible format are clear: source reduction, sustainability and convenience, but the transition to flexible packaging is less clear, largely due to the range of compatibility challenges when compared to rigid containers. Innovative film laminators seek to address these challenges with unique film combinations and processes.

Aggressive Content Compatibility / Acid & Alkaline Resistance

Unique substrate and material combinations allow aggressive contents to move to flexible packaging where formerly they were limited to rigid containers.

High Temperature Compatibility

Flexible formats often preclude high temperature processes such as hot-fill, however with the right film, extreme temperatures are no longer a problem.

Outstanding Barrier Properties

High barrier films offer enhanced protection against the permeation of water, vapor, gas, oil, oxygen, aroma, and light.

Superior Bonding Strength / Seal Through Powder & Oils

Unforeseen challenges in sealing flexible film pouches can arise when packaging oily or powdery products; high-strength bonds via inner sealant layers combat this issue.

Unique Finishes for Increased Shelf Appeal

Special film finishes and paper / film combinations like PPFP offer shelf appeal. Other examples include matte / gloss, frosted, metallic, and rice-paper.

Pantone Color Matching

The final “color” of a film is affected by the substrate on which the ink has been printed, custom film laminations are used to achieve exact Pantone® colors.

Interested in Learning More?

Whether you need a small volume order that other suppliers will not handle, or a custom lamination that is outside a supplier’s wheelhouse, our team can connect you with an appropriate specialist to deliver the solution you need.